For years, industrial wireless networks have been designed around a simple assumption: if you want reliable coverage, you build more towers. That approach worked when operations were static and predictable. But today’s industrial environments—mines, ports, rail yards, construction sites, and energy facilities—are anything but.

Operations move. Assets relocate. Terrain changes. Temporary infrastructure becomes permanent. And yet, we continue to force rigid, tower-centric wireless architectures into dynamic environments. The result is predictable: coverage gaps, rising costs, operational risk, and networks that struggle to keep pace with the work they’re meant to support.

It’s time to go beyond towers.

Providing insight into the subject of remote and mobile wireless communications, Andrew Martin, Vice President of Product Management and Strategy at Rajant Corporation, shares his experience in the field. Andrew shares why mesh-based systems are becoming essential for reliable network performance in today’s dynamic industrial operations.

The Limits of Fixed Wireless Thinking

Traditional wireless networks are built around fixed points of control. Towers, access points, and centralized cores define where connectivity exists—and where it doesn’t. In industrial settings, that rigidity quickly becomes a liability. As soon as equipment moves beyond coverage, or physical obstructions change the RF environment, performance degrades. Expanding coverage usually means building or relocating towers, which are expensive, slow, and often impractical in remote or temporary operations.

More importantly, tower-centric designs introduce single points of failure. When connectivity depends on a limited number of fixed assets, downtime becomes inevitable. In industries where automation, tele-remote operation, and real-time data drive productivity and safety, even brief interruptions can have serious consequences.

Mobility Changes the Network Equation

Industrial networks must follow the work—not the other way around. Vehicles, machines, autonomous systems, and personnel are already mobile. The network supporting them must be equally dynamic.

This is where mesh networking fundamentally changes the equation. Instead of relying on towers as the backbone, a mesh network distributes intelligence across the edge. Every node becomes both a user and a contributor to the network, allowing connectivity to extend organically as assets move. Coverage is no longer defined by where towers stand, but by where operations take place.

At Rajant, we built Kinetic Mesh® with this reality in mind. Our architecture treats wireless mesh and cellular links as peers within a single Layer 2 distributed network. Traffic is continuously evaluated and routed based on real-time conditions. If a path degrades or disappears, the network instantly adapts—without manual intervention and without disruption to applications.

Towers as Capacity, Not Constraints

This isn’t an argument against private LTE or 5G. Cellular technologies deliver tremendous value, particularly for high-bandwidth and wide-area coverage. The problem arises when they are treated as the foundation rather than a component.

In a mesh-centric architecture, towers become optional capacity instead of architectural anchors. They can be used when available and bypassed when they’re not. This dramatically reduces the number of towers required to achieve reliable site-wide connectivity, while also lowering congestion and improving overall network performance.

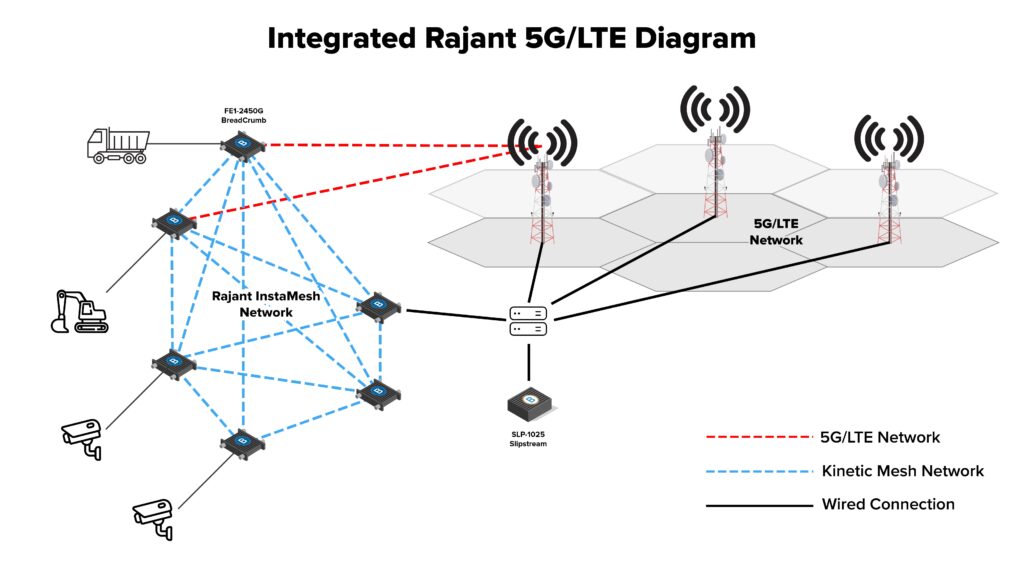

By integrating mesh directly with LTE and 5G (see figure 1 below) rather than layering one on top of the other, industrial operators gain flexibility. The network can dynamically choose the best path—mesh, cellular, or wired—for each packet, based on latency, throughput, and reliability requirements.

Figure 1. depicts a Rajant Kinetic Mesh network and the capabilities they have integrated with 5G/LTE networks with the new SLP-1025 and Hawk FE1-2450G BreadCrumbs.

Extending Reliability Beyond the Cell Edge

As industrial sites push further into automation and AI-driven systems, the demand for consistent, low-latency connectivity continues to grow. Small 5G cells alone can’t always meet that demand, especially in remote locations or environments with shifting layouts.

That’s why we’ve focused on extending mesh reliability into cellular environments. By combining high-performance wireless mesh nodes with integrated 5G/LTE capabilities, and enabling intelligent path selection at the core, we eliminate the traditional boundary between mesh and cellular networks. The result is a unified architecture that maintains application uptime even as assets move, conditions change, or infrastructure shifts.

This approach also simplifies deployment. Instead of building complex, tower-heavy architectures or relying on multiple temporary solutions like COWs, operators can design networks that are resilient from day one—and adaptable over time.

A Better Model for Industrial Wireless

Going beyond towers isn’t about abandoning existing infrastructure. It’s about rethinking how that infrastructure is used. Distributed, self-healing networks reduce risk, lower costs, and scale naturally with operations. They align with the realities of industrial work instead of fighting against them.

As industries continue to adopt autonomy, remote operations, and data-driven decision-making, the networks supporting them must be just as intelligent and resilient. Mesh networking provides a foundation—one where connectivity is no longer limited by where towers can be built, enabled by where the work actually happens. If you want to learn more on how our Kinetic Mesh network can enable better wireless communications for preexisting 5G/LTE, you can reach out to Andrew on LinkedIn. If you are inquiring about Rajant’s intelligent edge technology, then a Rajant representative will assist you in finding the best products for your site needs.

Alternatively, you can read our white paper on LTE/5G vs Kinetic Mesh technology.