Demands in Smart Warehouses

Seamless network reliability has become the backbone of efficient warehouse operations. Yet, maintaining consistent and reliable network coverage across vast, dynamic facilities remains one of the industry’s biggest challenges. Warehouses are complex environments—filled with metal shelving, moving vehicles, and constantly shifting inventory—that can disrupt traditional Wi-Fi and cellular signals. As automation, robotics, and real-time data tracking become standard, even brief lapses in wireless performance can lead to costly delays, safety concerns, and inefficiencies.

To provide deeper perspective on the evolving role of automation and advanced networking in warehouse environments. Brad Viernow, Sales Director at Rajant Corporation, shares his insights into the field. With experience in industrial wireless communications and automation integration, Brad shares his expertise with our Kinetic Mesh network and how your warehouse can best be optimized.

Warehouse Challenges

Understanding what can cause your network interference is the first step to a stable, continuous, and reliable network. With machinery, boxes, and people moving throughout the warehouse, it can be difficult to keep up with the modern network solutions. Rajant’s BreadCrumb nodes extend coverage and use InstaMesh technology to find and send packages using the fastest network path. Mobile BreadCrumb nodes can also alleviate some of these problems, placing them directly on assets creates a Machine-to-Machine (M2M) environment, instantly connecting them to the network.

Rajant Tech: Multi-Radio Mesh, Self-Routing, Scalability

Our Rajant Kinetic Mesh technology sets itself apart from other wireless mesh networks – experience resilient, redundant network communication with low latency and high bandwidth. Rajant BreadCrumbs operate within a specific set of frequencies and can be programmed to certain channels within the band. BreadCrumbs support 900 MHz, 2.4, 4.9, and 5 GHz but can accommodate other frequencies upon request if needed. These BreadCrumbs can send and receive on different frequencies, resulting in higher bandwidth speeds across multiple hops (mesh BreadCrumb nodes). The self-routing InstaMesh capability optimizes performance when nodes and frequencies are changed, finding the optimal route for packets to flow through. As your operations grow and expansions are made, it is essential to consider how this will impact your wireless communications. BreadCrumbs can scale with your network as your needs grow, extending coverage to even hundreds of BreadCrumbs, while increasing bandwidth. With the combination of all these advantages, data packets can reach their destination faster and with lower latency.

Mesh Layout Strategies

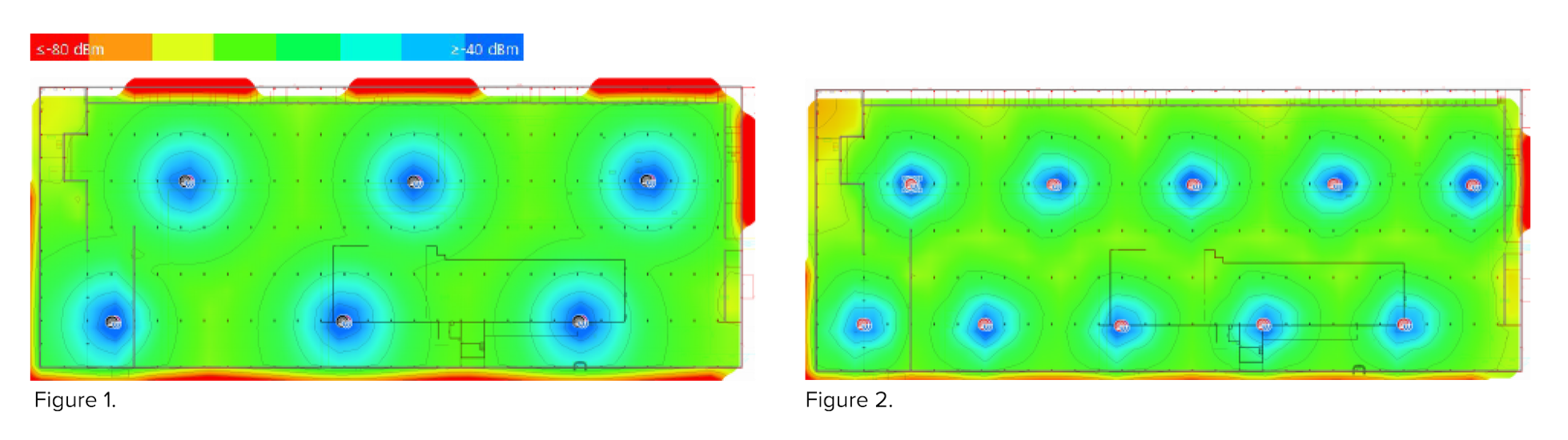

Figure 1. The image above depicts a total coverage map using Rajant nodes. It takes six Rajant nodes to cover this warehouse.

Figure 2. The image above depicts total coverage map using traditional Wi-Fi nodes. It takes ten nodes to produce the same coverage.

As you can see in the two figures above, Rajant outperforms the traditional Wi-Fi extender points by four additional nodes. Rajant’s mesh nodes offer 5x greater throughput, 5x lower latency, and 5x lower cost compared to other traditional networks such as LTE.

Integration with AGVs, Sensors, Edge Compute

Smart warehouses are a dynamic environment – lots of vehicles and boxes shifting around on the floor. For operations to move smoothly, these autonomous ground vehicles (AGVs) and autonomous mobile robots (AMRs) often need to communicate with each other so they can move around with any obstacles.

Warehouses rely on sensors to track many different assets within warehouses, some of these include environmental sensors, asset-tracking tags, and machine health monitors. Dead zones for signals reduce the efficiency a warehouse can operate at.

Testing, Metrics, and Fault Recovery in the Kinetic Mesh Network

To get the full grasp of determining how large your mesh network is, node placement testing will occur on your site. Engineers will test and see how well the mesh will perform in your warehouse. Bench testers communicate to see how each node handles your assets and any interference within the warehouse. Next, the pilot for the mesh network will be applied, measuring the real-time performance and understanding how the device changes between nodes when they move.

After the Kinetic Mesh network is successfully deployed, there are some factors that must be taken into consideration to understand how to keep your network running efficiently, such as packet delivery ratio (PDR), latency (ms), jitter, throughput (Mbps), node uptime, handoff delay, and self-healing time. Our network management system, BC|Commander Suite, is designed to acknowledge all these factors, sending alerts if there is a change.

Rajant’s solution for no network gaps is through InstaMesh, designed to reduce downtime. In the case that one node goes offline, the network will self-heal and find the best route for packets to travel. This ensures no single point of failure for your network. Edge-based backup controls allow robots to keep moving safely until full communication is restored. BC|Commander can send alerts based on different factors in your mesh network, ensuring you are one-step ahead of any issues.

ROI Arguments

Every connected asset is vital for warehouse operations to move smoothly – sensors, robots, vehicles and more. Gain safer, faster, more precise control over your warehouse knowing where your assets are. Reduce repetitive tasks using automated robots, while orders move faster through the warehouse. Less errors occur when you automate your network, the failproof mesh network ensures that it will always stay on. Our scalable network allows you to add nodes efficiently, whether expanding it with new robots, systems, or more.

If you are interested in learning more about what our BreadCrumb products and Kinetic Mesh technology will do for your operations, you can directly reach out to Brad through LinkedIn. Otherwise, transform your warehouse into a smarter, more resilient operation today and contact a Rajant representative to learn more about our Kinetic Mesh technology.