In today’s petrochemical industry, uptime, safety, and efficiency are everything. Yet many facilities still rely on network infrastructures that can’t keep up with the growing need for real-time visibility and control. Rajant’s Intelligent edge is changing the way refineries operate, offering seamless wireless communication which increases productivity and keeps your staff safer. It delivers reliable, always-on wireless communications to the edge, no matter how vast or complex. This technology empowers operators to make faster, smarter decisions while maintaining the highest safety standards. From monitoring remote assets to enabling industrial AI, Rajant’s intelligent edge solutions provide the flexibility and resilience that modern petrochemical operations demand.

To help shed light on the role Rajant’s intelligent edge technology plays in today’s petrochemical industry, JL Betts, VP Sales for Oil/Gas/Utilities in North America, speaks how Rajant’s Intelligent Edge solutions can assist bringing wireless communication throughout the entire site. JL understands the challenges of keeping operations safe, efficient, and always connected.

Wireless in Hazardous Areas

Gain the advantage and enhance safety and reliability on your site with our Rajant’s intelligent edge technology. When utilizing the Kinetic Mesh network, our nodes reduce the need for widespread cabling throughout your site, spend less time worrying if the cabling will get physical damage. When you power the Industrial Internet of Things (IIoT) integrating your assets to the ecosystem creates ease of access management of your operations. Operators gain instant insights into equipment performance, environmental conditions, and safety alerts, allowing for more informed and faster decisions that prevent not just downtime, but also safety on the site.

ROI Benefits Using Kinetic Mesh Technology

Rajant’s Kinetic Mesh networks don’t just bring wireless communication to the table, it delivers returns across operations, safety, and more. Here are some of the ways that Kinetic Mesh can drive results for your hazardous plant:

1. Surveillance and Safety Measures – Protect the facility from unwanted communications and provide tracking for assets and individuals. The Kinetic Mesh network can provide GPS-based locations with status updates, ensuring operators can efficiently communicate.

2. Communications and Platform Monitoring – Communicate on the Kinetic Mesh network using reliable wireless communication. Operators can monitor all platform cameras, sensors, vehicles, equipment and more.

3. Mobility – BreadCrumbs move throughout your site with your assets to provide full coverage, optimizing the best route for packets to flow through, even with interference.

Rajant Node Features & Options for Hazardous Zone Use

Here are a few different recommendations for petrochemical plants and refinement zones:

1. Sparrow BreadCrumb – This IP67 radio is built for industrial IoT heavy-duty applications such as heavy machinery, moving assets, and security monitoring.

2. Cardinal BreadCrumb – Our most lightweight and smallest BreadCrumb, the cardinal is best used for robotics and creates fully mobile M2M communications, as well as being the wireless backbone of SCADA, PLC or RTU communication.

3. Peregrine AX BreadCrumb – a high-performance industrial-grade BreadCrumb platform that offers throughput speeds up to 3.5Gbps and the highest level of enhanced security performance.

4. Cowbell – is a purpose-built distributed computing hub and OS platform for real-world operational demands requiring real time AI driven analytics and machine learning for safety and security applications to name a few.

Consult with one of our Rajant team members and they will help you determine which BreadCrumb nodes fit for your specific site needs.

Deployment Scenario

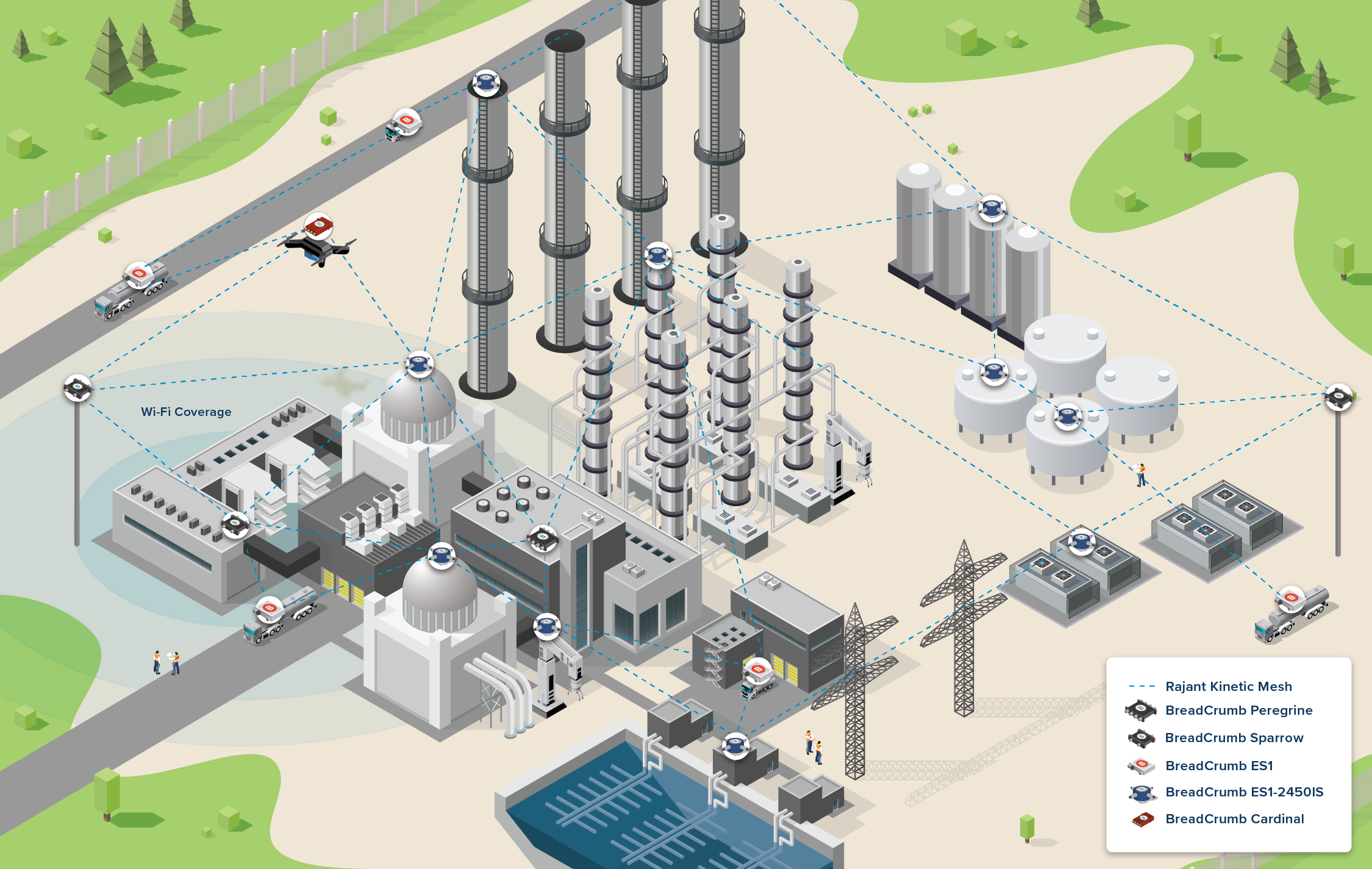

Figure 1. This deployment scenario depicts a petrochemical oil facility and how Rajant BreadCrumb nodes interact with different assets of the plant.

This deployment scenario depicts a variety of different assets that are found within petrochemical plants, whether it is smart lighting, surveillance, laptops, or moving assets such as vehicles/drones. Rajant’s intelligent edge technology ensures near-zero downtime using InstaMesh technology, utilizing its self-healing node properties and finding the fastest point of connection.

Case Study

This case study explores how this producer tackled wireless communication demands with real-time monitoring and consistent up time. They integrated our BreadCrumb network nodes into their existing network infrastructure, eliminating the need to do a forklift wireless replacement and building additional control towers. This creates a hybrid approach, combining the current infrastructure but optimizing it to its full potential using BreadCrumb nodes, bringing it to the edge without having any system or site downtime. Using the power of InstaMesh, the network was able to overcome any obstacles using our resilient self-healing protocol to find the best frequency for data to transfer. This increased the network uptime and reliability across the entire site. Rajant’s Kinetic Mesh network increased throughput speeds from the existing 700k to 25MBps average (maxing at 3MBps) compared to other traditional fixed networks.

Maintenance for Your BreadCrumbs

Understanding the importance of routine inspections and monitoring your BreadCrumb nodes will help you address any issues and minimize the amount of downtime needed. BreadCrumbs can be managed through BC|Commander Suite, where updates can be sent and installed to each node through your network. Keeping up to date with your assets will minimize the amount of configuration drift BreadCrumbs will have, preventing and updating measures as necessary.

If you’d like to connect with JL to learn more about implementing resilient wireless solutions in your refinement facility, you can continue the conversation on LinkedIn. If you’re ready to transform your operations, you can contact a Rajant representative to see how Rajant’s Intelligent Edge technology delivers continuous performance where traditional networks fall short.

LinkedIn

LinkedIn