Providing wireless fidelity and enabling long term network evolution without the limitations of Wi-Fi or the complexity hassles of LTE

Thinking Forward

“FutureSmart Mining™ is Anglo American’s innovation-led approach to sustainable mining. It’s a response to the global drive for safer, more efficient, and more sustainable ways to mine. Our ability to innovate—to evolve, adapt, and improve—will give us a decisive competitive advantage. So FutureSmart Mining™ is also an investment in our future.”

The above was a project introduction given by Hendre van Rooyen, Anglo American IIT Network Infrastructure Specialist, to SCAN RF Projects, an advanced industrial systems integrator.

In addition, Anglo IIT tasked SCAN RF to find a solution to the costly and cumbersome excessive reliance on fiber infrastructure in underground mining communication solutions.

“The very dynamic and sometimes harsh nature of underground mining makes it extremely difficult to constantly deploy, change or add to our underground fiber infrastructure. This is especially true of the more dynamic areas closer to the active mining face,” was an additional reflection from Mr. van Rooyen.

SCAN RF Projects tasked their senior engineering resources to investigate, test and benchmark different technologies with the potential of servicing the Anglo American IIT requirement.

“We approach requests like these by taking a product agnostic stance. This enables us to approach customer requests without bias and guarantees that the eventual technology or product choice is purely based on performance and adherence to the customer requirement,” said Jean Schroder, Sales and Business Development Director at SCAN RF Projects.

Months of testing resulted in some very surprising findings that challenged previous assumptions. It became apparent that both LTE technology, as well as enterprise Wi-Fi solutions, performed lower than expected and did not have an apparent solution to the excessive reliance of fiber infrastructure.

During these trials, Anglo American IIT and SCAN RF Projects also approached Rajant Corporation to test the performance claims of our Kinetic Mesh® technology.

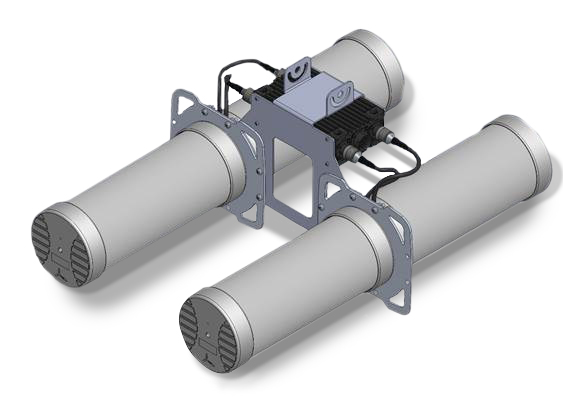

By combining the strengths of the Kinetic Mesh and a purpose-built underground antenna array specially developed by Poynting Antenna, a solution was found, which both met and frequently exceeded the performance expectations of the customer.

The Poynting Heli-22 antenna array specially developed for bi-directional multi-band linear meshing.

Core to the solution is the ability of Rajant’s technology to do “Linear Meshing.” This feature utilizes the multiple RF interfaces of a Rajant Mesh node to effectively do multiple wireless hops whilst losing negligible throughput. This feature can provide connectivity over long distances underground equating to several kilometers and delivers on the requirement of minimal reliance on fiber infrastructure.

Mesh node to mesh node tests were done over distances of up to 1Km with multiple tunnel bends obstructing line of sight. Even in these circumstances a consistent TCP throughput of ~70Mbps was still achieved at around 700m. At 1Km, a constant throughput of 25Mbps was still achieved. It is very important to note these results were achieved with no line of sight.

The final test results prompted Anglo American IIT to order 110 Rajant BreadCrumb® Nodes, which were deployed in their Amandelbult platinum mine. Another project is currently underway and will be deploying approximately 50 BreadCrumb nodes at their Unki mine in Zimbabwe. In addition, two additional future projects are expected to put the Anglo Group’s total amount of Rajant BreadCrumbs deployed underground at almost 500.

Mine officials can now work smarter, faster with more ease while underground, as they can now use their tablets to capture visible felt leadership (VFL) tasks, planned task observations (PTO), safety inspections, SharePoint access and follow-ups for previous inspection deviations. 🖉